FDA issued a Warning letter to Amman Pharmaceuticals following inspection at the facility (FEI 3013501887) at Amman, Jordan in August 2023. The Warning letter highlights critical lapses including non aseptic operations and inadequate controls to prevent microbial contamination of sterile products, design flaws of aseptic lines, unreliable environmental monitoring and microbial control data, failure to validate aseptic and sterilisation processes. Laboratory data are not trustworthy and Quality Unit (QU) failed to ensure reliability of data and oversight. Amman Pharmaceuticals is a contract manufacturer for several sterile over-the-counter (OTC) sterile eye drops and eye ointments and homeopathic drug products exported to US.

Warning letter

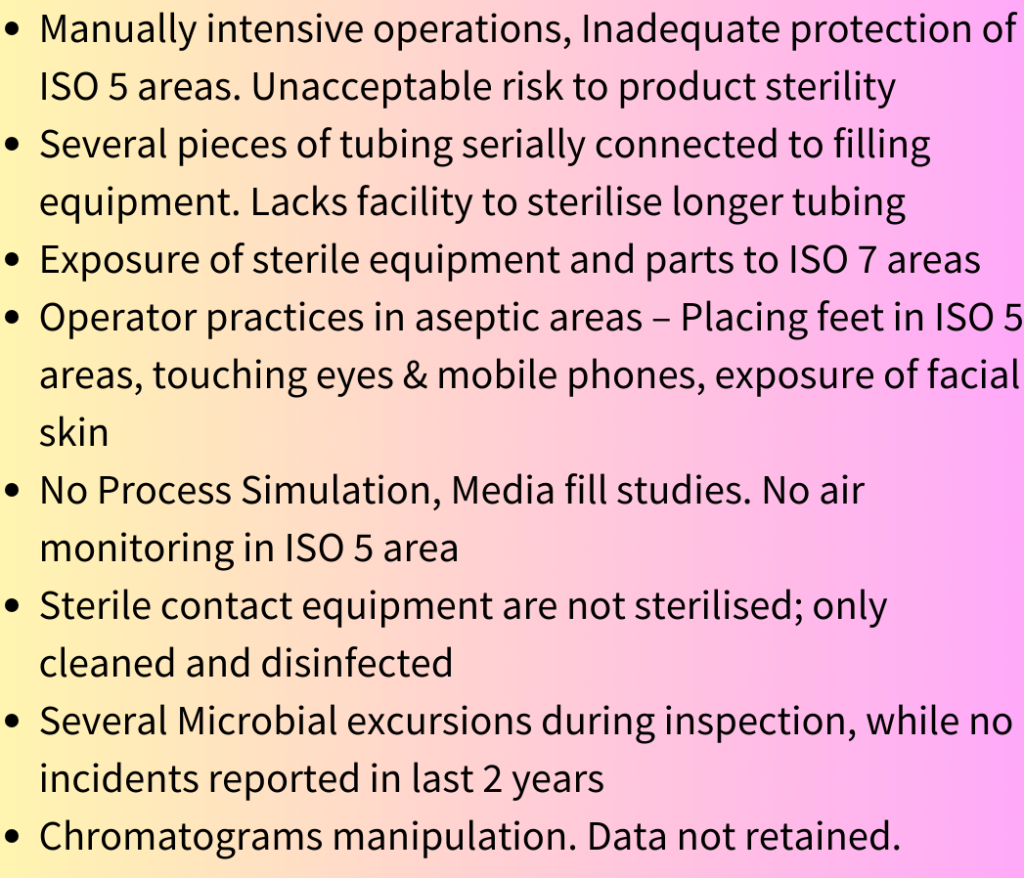

The issues detailed in the Warning letter are:

- Aseptic areas and facilities, controls, systems are inadequate to prevent contamination. Risk to product sterility due to manually intensive operations, inadequate protection of ISO 5(Grade A) areas, excessive aseptic connections (multiple small pieces of tubing’s are serially connected to reach filling equipment as the facility cannot sterilise long tubings), poor equipment design lacking smooth surfaces for easy cleaning and disinfection. Poor aseptic area practices of operators – sterile hopper exposed to ISO 7 area during set up and operator placing their feet in ISO 5 enclosure. Environmental monitoring of aseptic areas (ISO 5)– air monitoring, surface monitoring, personnel monitoring are inadequate. Microorganisms isolated during Environmental monitoring are not identified. There were no airflow studies under dynamic conditions. In microbial monitoring during inspection several excursions were observed, while there were no such incidents reported during past 2 years. In the Warning letter USFDA reminds that while sterility test is a critical quality control for aseptically produced products, it cannot be solely relied as justification as test is only the last in a series of design provisions and controls.

- Inadequate or no validation of aseptic and sterilisation processes. Process simulation studies, media fill studies are not conducted, all interventions not documented. Observed operator interventions and practices like exposure of facial skins, operators crawling below filling machine on hands and knees, operator touching eyes, mobile phones, and product hosing above open vials. Multiple pieces of equipment like hoppers, tracks were not sterilised and only cleaning and disinfection practiced

- Laboratory records lack complete and trustworthy data – Numerous actional recoveries from ISO 5 areas observed during inspection, while no such incidents are reported in past two years. Analytical Chemists are able to manipulate chromatograms; no meta data is retained from HPLCs.

- Quality unit failed to implement effective procedures and conduct adequate oversight to ensure accuracy and reliability of data and records.

Leave a Comment

You must be logged in to post a comment.