Discussion forum for Pharma Quality events, Regulatory Actions

Warning letters, 483s, Recalls, Import Alerts, Audit observations

Warning letters, 483s, Recalls, Import Alerts, Audit observations

Laurus, Visakh was issued USFDA 483 with five (5) observations following USFDA inspection by investigators Joseph A. Piechocki and Rafeeq A. Habeeb in Dec 2023. The observations cite lapses in investigations of equipment damage and potential particulate contamination, OOS investigations; deficiencies in sampling to ensure representativeness of the batch, deficiencies in cleaning, verification and maintenance of equipment, lapses in documentation and control. (USFDA 483)

Qvent review the observations in a series of 3 posts. In this post Qvents review the observations of Inadequate investigation into Equipment Damages, particulate contamination, OOS investigations

Other related posts are:

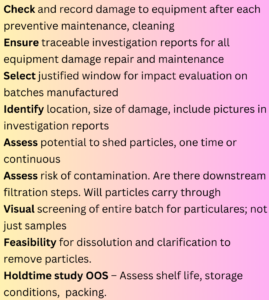

Only samples from batches after product change over cleaning were evaluated for particles by filtration test; but entire batch was not screened for particles, which lack scientific rationale. Investigations stated the batches met the specifications, there is no impact and the batches were consumed in further stages. Customers were not informed about the deviation. The investigations claimed that the particles would be removed by the downstream filtration steps and do not affect product quality, but did not provide any scientific evidence or documentation for the same.

Only samples from batches after product change over cleaning were evaluated for particles by filtration test; but entire batch was not screened for particles, which lack scientific rationale. Investigations stated the batches met the specifications, there is no impact and the batches were consumed in further stages. Customers were not informed about the deviation. The investigations claimed that the particles would be removed by the downstream filtration steps and do not affect product quality, but did not provide any scientific evidence or documentation for the same. Only samples from batches after product change over cleaning were evaluated for particles by filtration test; but entire batch was not screened for particles, which lack scientific rationale. Investigations stated the batches met the specifications, there is no impact and the batches were consumed in further stages. Customers were not informed about the deviation. The investigations claimed that the particles would be removed by the downstream filtration steps and do not affect product quality, but did not provide any scientific evidence or documentation for the same.

Only samples from batches after product change over cleaning were evaluated for particles by filtration test; but entire batch was not screened for particles, which lack scientific rationale. Investigations stated the batches met the specifications, there is no impact and the batches were consumed in further stages. Customers were not informed about the deviation. The investigations claimed that the particles would be removed by the downstream filtration steps and do not affect product quality, but did not provide any scientific evidence or documentation for the same.Equipment Damage & Investigations

During preventive maintenance activity (PM) and product change over cleaning, verify equipment for damages and document. This can help in identifying issues proactively, narrow down the window for number of batches to be evaluated when an equipment damage is observed.

During preventive maintenance activity (PM) and product change over cleaning, verify equipment for damages and document. This can help in identifying issues proactively, narrow down the window for number of batches to be evaluated when an equipment damage is observed.OOS Investigations / Hold time failures

Inadequate assessment of potential particulate contaminations poses risk to product quality and safety and also has regulatory consequences. When such issues are reported a comprehensive assessment shall be performed and remediation actions taken.

Review and enhance procedures for Hold time studies and OOS investigations addressing aspects to be investigated in case of failures – assessment of packing, shelf life, storage conditions for Hold time study failures; review of TAMC trends in case of TOC failures.

Leave a Comment

You must be logged in to post a comment.